Preventing Weld Undercut Made Easy: Trick Techniques Introduced

Preventing Weld Undercut Made Easy: Trick Techniques Introduced

Blog Article

Recognizing the Causes and Solutions for Undercut Welding in Steel Fabrication Processes

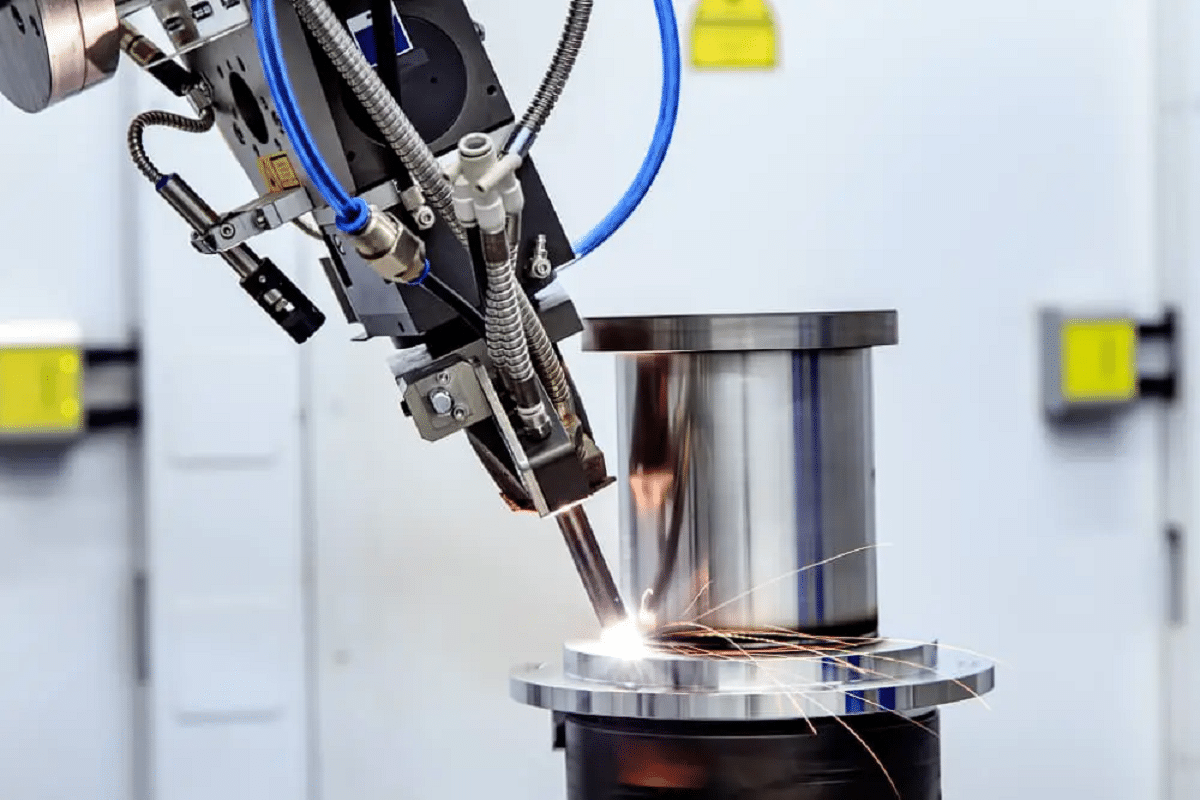

In the realm of steel fabrication procedures, the event of undercut welding postures a considerable obstacle that demands a comprehensive understanding of its reasons and sensible options. The complex interaction of different elements during welding procedures can cause this unfavorable phenomenon, influencing the architectural integrity and overall quality of the welded joints - Preventing weld undercut. By exploring the source of undercut welding and checking out efficient therapeutic steps, makers can raise the standard of their handiwork and guarantee the production of flawless steel elements

Typical Root Causes Of Undercut Welding

Frequently neglected in metal manufacture, undercut welding occurs due to various factors that demand precise attention and competence to be properly minimized. In addition, incorrect welding techniques, such as making use of the incorrect welding angle or travel rate, can likewise contribute to damage development. The selection of welding criteria, such as voltage, existing, and cable feed rate, plays a substantial function in the event of undercut welding.

Effect of Incorrect Welding Parameters

Incorrect welding criteria can considerably jeopardize the honesty and top quality of welded joints in metal fabrication processes. The influence of inaccurate welding criteria shows up in different methods, leading to structural weaknesses and problems in the bonded parts. One critical element affected by improper welding specifications is the penetration depth of the weld. Insufficient warm input as a result of low welding currents or excessively high traveling speeds can lead to poor fusion between the base metals, bring about incomplete joint penetration and weakened bonds. Alternatively, excessive warmth input triggered by high welding currents or slow-moving travel rates can cause too much and burn-through reinforcement, creating a breakable and unsteady weld framework. Additionally, wrong specifications such as improper voltage settings or incorrect electrode angles can contribute to erratic weld grain accounts, absence of combination, and increased chances of flaws like damaging. Precise interest to welding parameters is paramount to guarantee the production of high-quality welds with the wanted mechanical buildings and architectural honesty.

Result of Improper Lantern Angle

Improper torch angle in welding operations can dramatically affect the high quality and honesty of the final weld joints in metal fabrication processes. Undercutting is an usual welding flaw where a groove creates along the weld toe, deteriorating the joint and endangering its structural stability.

A torch angle that is too steep can cause inadequate infiltration, incomplete blend, and enhanced spatter. On the other hand, a torch angle that is too shallow can cause excessive penetration, burn-through, and distortion of the base product. Preventing weld undercut. Correct lantern angle is vital for making certain constant weld quality, strength, and appearance

To stop damaging and various other issues brought on by inappropriate lantern angles, welders must be trained to maintain the right torch angle throughout the welding procedure. Normal tracking and adjustment of lantern angles during welding can help achieve sound welds with very little issues.

Function of Inadequate Welding Methods

One more element of insufficient welding strategies is inappropriate weld preparation. Poor cleansing of the base metals, inaccurate joint layout, or not enough edge prep work can all contribute to damage welding. Poor protecting gas protection or using the incorrect kind of gas can result in insufficient combination and the formation of undercut problems.

To attend to the role of inadequate welding strategies in metal manufacture processes, it is important to supply detailed training for welders. Appropriate education and learning on welding specifications, joint go prep work, and shielding gas choice can assist avoid undercut welding and make certain top quality welds in metal manufacture jobs.

Effective Solutions for Undercut Welding

Dealing Going Here with undercut welding in steel manufacture requires implementing efficient solutions to enhance weld top quality and structural stability. Among the key solutions to combat undercut is to readjust welding parameters such as voltage, current, and travel rate to make certain appropriate warmth input and blend. By fine-tuning these setups, welders can protect against too much melting of the base steel and filler product, minimizing the possibility of undercut formation.

In addition, correct joint prep work is critical in protecting against undercut. Guaranteeing clean base metal surfaces without contaminants and making use of the proper bevel angle can assist promote far better weld penetration and decrease the risk of undercut - Preventing weld undercut. Using appropriate welding methods, such as oscillating the torch or weaving, can additionally help in distributing warmth uniformly and filling the weld joint adequately, reducing the possibility of undercut problems

Furthermore, choosing the proper welding consumables, consisting of electrodes and filler metals, is crucial in alleviating undercut. Making use of materials with appropriate chemical structures and mechanical residential or commercial properties can add to accomplishing audio welds with marginal undercut. Regular evaluation and quality assurance procedures must additionally be implemented to spot and attend to undercut concerns promptly, making sure the general stability of produced steel elements.

Final Thought

In verdict, recognizing the reasons and remedies for undercut welding in steel manufacture procedures is essential for accomplishing premium welds. By attending to usual causes such as inaccurate welding specifications, inappropriate torch investigate this site angle, and inadequate welding techniques, welders can prevent undercutting and make certain strong, sturdy welds. It is important to take notice of these aspects and apply efficient services to boost the total welding procedure and final item high quality.

Report this page